-

Heat recovery - ECOVENT

SUPERECOVENT with subsequent exhaust air condensation

SUPERECOVENT

ECOVENT DUPLEX retrofitting

ECOVENT SOLAR

ECOVENT DUPLEX

ECOVENT III

ECOVENT II

ECOVENT

-

Heat recovery - LUVO

LUVO IV

LUVO III

LUVO II

LUVO I

-

Efficient airflow and circulation

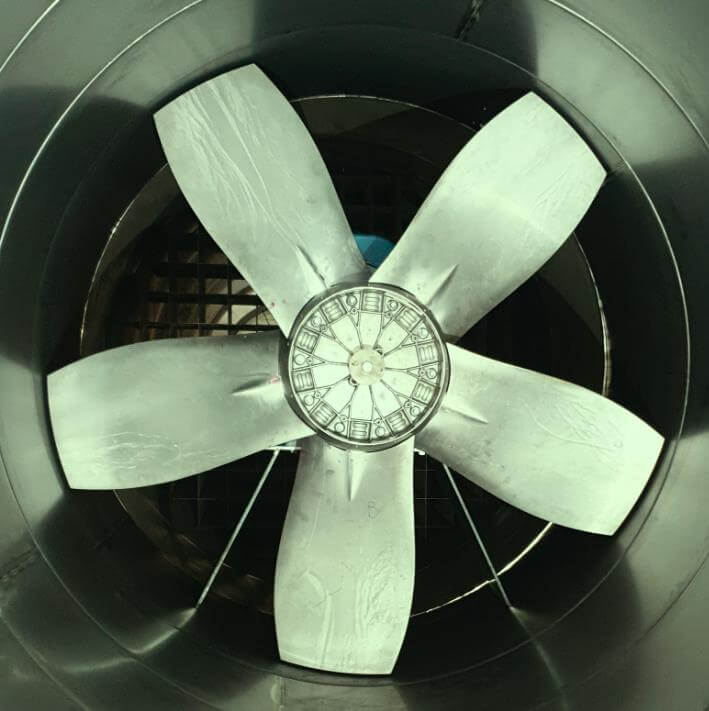

PENTAVENT

CRT drying program

DUO-FAN

MAHILD AIR

UNI-VENT

TURBO-VENT

VARIFLEX

-

Intelligent control

Modern user interface

Control software gets a modern user interface

Multiple SCADA options

The Mahild control software can be implemented with the following user interfaces: WINCC, Wonderware/AVEVA, Intouch, Citect, RSView.

CLIMATE MULTI-MEASURING

The new MM4100 control system with CLIMATE MULTI-MEASURING is used for the first time in Europe.

Mahild remote maintenance

With the latest version of the Mahild computer control system with industrial hardware and software, it is possible for the first time to carry out programme adjustments remotely.

Energy manager ECO-HEAT

Energy management according to the latest standards. The available thermal energy is used as required -- where the productivity of the kiln requires it and where the quality of the material to be dried dictates it. The results are uniform boiler loads, increased boiler efficiency and reduced emissions and downtimes.

Introduction of the computer control MM4000

From now on, Mahild lumber drying kilns are controlled by our own computer control system and can be individually adapted to the customer's needs.

-

Wood moisture measurement

PROZONE wireless

From now on, wood moisture readings can be wirelessly transmitted to the control system.

PROZONE meets CONTRAFLOW

The PROZONE wood moisture measuring device was successfully used in the CONTRAFLOW kiln for the first time.

MULTI-HUM

Adapted to each customer, each kiln and each Species, the Multi-Hum estimates the moiture content during the entire drying process. Using research performed by our own wood technologies engineering team, we were able to develop a formula that uses the current conditions in the kiln to determine a very accurate moisture measurement, eliminating the need for wired probes or any other type of direct measuring of moisture.

Weight based wood moisture measuring system

New weight based wood moisture measurement system is introduced. High-precision scales inside the drying chamber weight single board samples, wood stacks or complete chamber batches to measure the wood moisture.

PROZONE

Zonal wood moisture measuring system is introduced. The average moisture content of several cubic metres of wood can be determined per zone.

Control system MM 8500

Market launch of the trend-setting control system MM 8500, equipped with:

- Automatic drying guidance without wood moistness sensors.

- Wireless wood moisture measurement.

- Weight measurement according to the principle of sample boards.

Weighing system

Introduction of a new method for the determination of the wood moisture content by means of weight measurements of the entire dryer batch.

-

More innovations

OXI-VENT

A uniform colouring of the wood can only be achieved in a completely saturated steam atmosphere. The OXI-VENT system ensures perfect conditions in the steaming chamber, so that uniform wood colouring is achieved and steaming times are significantly reduced.

MAHILD LOW NOISE

Special new materials and construction improvements decisively absorb the fan noise. Noise emissions are reduced while energy consumption is minimized.

TOP-PRESS

During lumber drying, natural shrinkage often causes deformation, especially of the upper layers of boards. These deformations can be prevented or limited by the application of weights.

The Mahild TOP-PRESS system takes over this task reliably, safely and automatically. One push of a button is enough and the wood stacks in the dryer are loaded with a continuously adjustable load. A constantly high pressing pressure - or one that is automatically adjusted to the drying process - ensures dimensionally stable board material even in the upper layers of the stacks.